High-density heat is the new bottleneck. Which liquid cooling and heat rejection strategies are best equipped to handle it?

The design of a data center liquid cooling system directly impacts uptime, efficiency, and scalability. With rack densities pushing 200 kilowatts (kW) and artificial intelligence (AI) chips drawing over 1000 watts (W) thermal design power (TDP) ratings, cooling begins at the architecture behind coolant distribution units (CDUs).

How CDUs are configured determines how heat is transferred, where it’s rejected, and what systems support it.

CDU configuration choices affect key thermal management factors including airflow routing, fluid interface compatibility, space utilization, and alignment with site-specific cooling infrastructure. Selecting the right architecture starts with understanding how each one manages heat and what that means for scale, density, and infrastructure planning.

Learn more

Understanding Coolant Distribution Units (CDUs) for Liquid Cooling

Every liquid cooling deployment starts with one question: how will heat move through your system? This piece explains what CDUs are, how they work, the types available, and where each one is most effective.

Types of heat rejection methods

Liquid-to-liquid CDUs

Liquid-to-liquid CDUs (see Figure 1) transfer heat from IT equipment to the facility’s chilled water supply (FWS) through a plate heat exchanger. A dedicated secondary loop or technology cooling system (TCS) circulates coolant through server cold plates, absorbing heat before returning it to the CDU. The two loops stay hydraulically isolated, preventing fluid mixing. Liquid-to-liquid CDUs require chilled water infrastructure to properly remove the heat. Data centers without existing systems may need significant plumbing and pump installations to effectively deploy liquid cooling.

Figure 1. The Vertiv™ CoolChip CDU 2300 is designed for efficient liquid-to-liquid heat exchange in high-density environments.

Liquid-to-air CDUs

Liquid-to-air CDUs (see Figure 2) disperse heat through a heat exchanger coil system and use fans to cool the fluid, allowing operation regardless of access to a chilled water system. This simplifies installation and cuts initial costs by leveraging existing air-cooling infrastructure. However, it is important to note that liquid-to-air and liquid-to-liquid CDUs exhibit distinct thermal performance characteristics. These differences must be assessed against the specific operational requirements of each application for accurate and supportable performance comparisons.

Figure 2. The Vertiv™ CoolChip CDU 70 functions as a liquid-to-air heat exchanger for cooling chips.

Liquid-to-refrigerant CDUs

Liquid-to-refrigerant CDUs (see Figure 3) use direct expansion (DX) refrigerant-based technology to remove heat from the data center. These systems are designed to support modular installations, enabling operators to deploy liquid capacity when and where they need it while maximizing efficiency through pumped refrigerant economization (PRE).

Figure 3. Vertiv™ CoolPhase CDU is a liquid-to-refrigerant CDU, designed to remove barriers to liquid cooling in air-cooled environments.

Watch: Hybrid liquid cooling technology for rapid AI deployment | Vertiv™ CoolPhase CDU.

Comparing CDU configurations

In-rack CDU

In-rack or rack-mounted CDUs (see Figure 4) deliver localized cooling by embedding the CDU within the rack. This enables rack-level thermal control, easier deployment in edge sites or retrofits with limited facility liquid infrastructure, and reduces the impact of potential cooling outages to one rack instead of multiple. This type of design reduces system dependencies but adds mechanical complexity inside the rack, potentially affecting cable management, airflow, and serviceability. Limited capacity also makes this setup less suited for larger-scale deployments.

Figure 4. Vertiv™ CoolChip CDU 100 is an in-rack unit for single-rack direct-to-chip cooling. It lowers secondary fluid volume and simplifies infrastructure designed to deliver 100 kW of liquid cooling through liquid-to-liquid heat exchange.

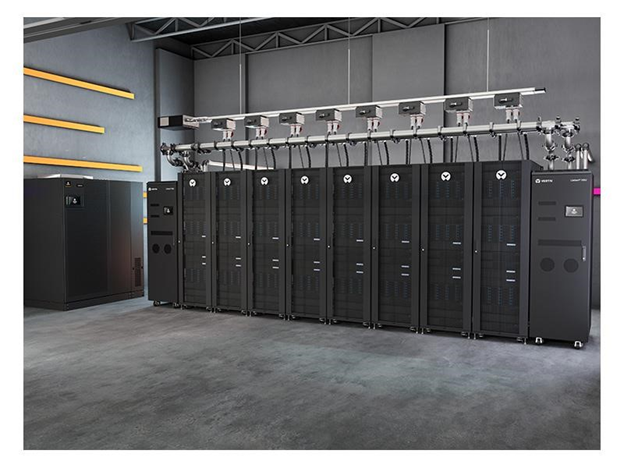

In-row CDU

In-row CDUs (see Figure 5) centralize cooling between racks, balancing rack-level control with shared infrastructure. They reduce the number of CDUs while enabling scalable liquid distribution. This configuration supports hybrid cooling strategies but requires careful design to avoid thermal imbalance and maintain redundancy. Pipe routing, service access, and failure domain isolation are critical considerations, especially in compact, high-density environments.

Figure 5. A 3D rendering of Vertiv™ Liebert® XDU450 CDU installation

Gallery CDU

Gallery CDUs are facility-scale systems positioned at the perimeter or in mechanical corridors. They provide centralized thermal management for large, dense deployments with advanced monitoring and coordinated distribution. These systems support dynamic load balancing and full integration with facility controls. However, they require extensive planning for layout, piping, and control logic—and assume higher operational maturity to manage system-wide cooling at scale.

| CDU Type | Advantages | Considerations | Best Use Cases |

|---|---|---|---|

| In-rack | - Rack-level cooling - Short fluid loop - Streamlined and standardized installation |

- Occupies rack space - More units, more maintenance - Performance metrics vary with deployment size |

- Small/GPU-heavy setups - Mixed environments - Rapid rollouts |

| In-row | - Cools multiple racks - Fewer units to manage - Modular design supports scalability |

- More plumbing required - Central failure risk - Needs load balancing |

- High-density racks - Small to large data centers - Flexible, scalable cooling capacity |

| Gallery | - Cools multiple rows - Scalable architecture - Coordinated system control |

- Higher install & maintenance costs - Needs perimeter or gallery space - Complex management |

- Large-scale builds - High-density deployments - Centralized cooling design |

Wrapping up liquid cooling architectures

Heat rejection strategies vary in complexity, scalability, and energy performance, depending on the design and deployment model. CDU configurations scale differently and suit different floor layouts. Cooling design should align with current site conditions and operational needs, particularly in environments with elevated thermal demands.

Design for density, plan for growth

Find the cooling solution that fits your data center’s needs, with the right design, support, and expertise to match. Contact Vertiv today to discuss your data center cooling requirements.