Liebert® XDU450 Coolant Distribution Unit

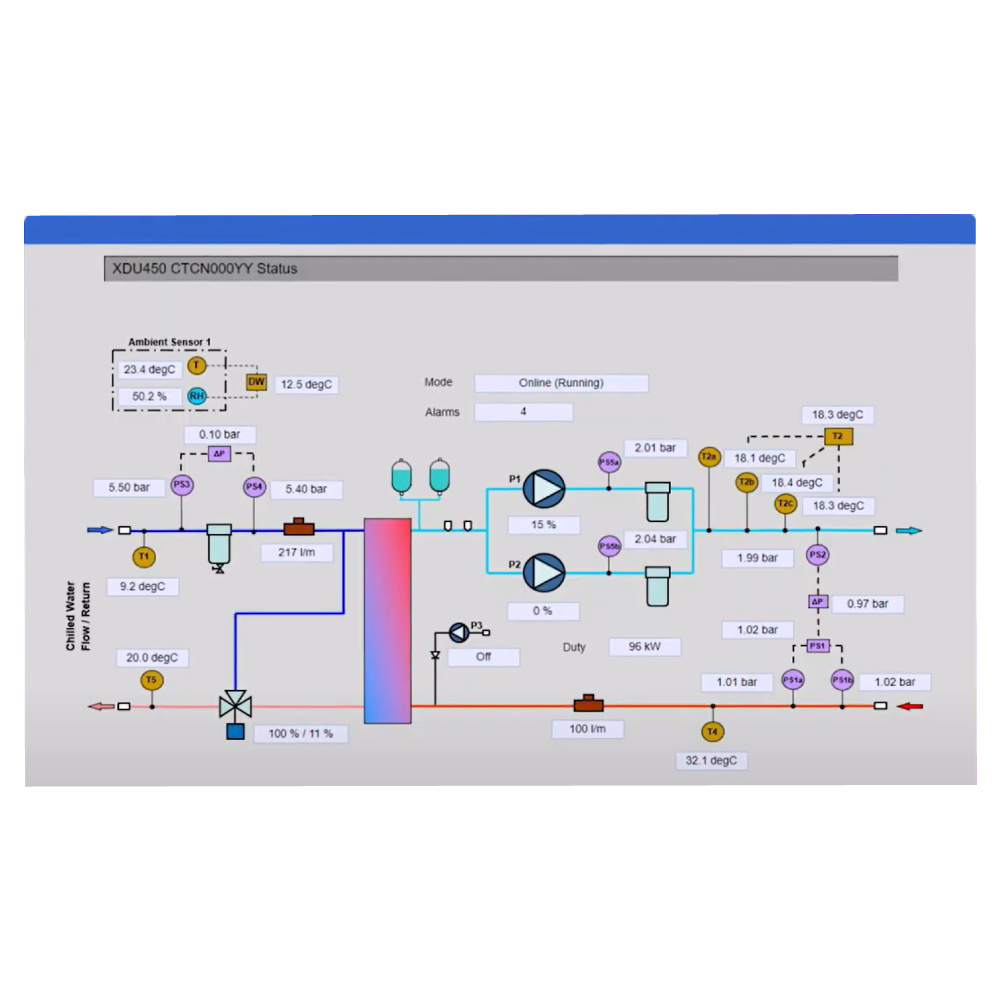

The Vertiv™ Liebert® XDU450 Coolant Distribution Unit is designed to support liquid cooling within high density environments. It is suitable for chip and rear door cooling applications. It offers easy, cost-effective deployment in any data center. It uses a liquid-to-liquid heat exchange method to efficiently support higher rack densities while maintaining optimal system conditions.

Saved This Product to Your Dashboard

You just saved this product to your dashboard to view at a later time. You can easily remove the item from your dashboard when you no longer wish to have it saved.

Please login or create an account to save this for later

- Data Center/Colocation/Hosting

- Education

- Government

- Healthcare

- Retail and Wholesale

Liebert® XDU450 Coolant Distribution Unit

The Vertiv™ Liebert® XDU450 Coolant Distribution Unit is designed to support liquid cooling within high density environments. It is suitable for chip and rear door cooling applications. It offers easy, cost-effective deployment in any data center. It uses a liquid-to-liquid heat exchange method to efficiently support higher rack densities while maintaining optimal system conditions.

- Data Center/Colocation/Hosting

- Education

- Government

- Healthcare

- Retail and Wholesale

Benefits

Features

Specifications

Seamlessly transition to high-efficiency liquid cooling technology with Vertiv™ CoolChip CDU (next generation of Vertiv™ Liebert® XDU family). From hyperscale and colocation environments to edge applications, the Vertiv CoolChip CDU offers flexible deployments for rear door heat exchangers or direct contact liquid cooling. It allows for in-rack, end of row, or perimeter placement options. Easily distribute coolant to efficiently manage power dense deployments with liquid-to-liquid heat exchange up to 100 kW, 450 kW, 600 kW, or 1,350 kW, and liquid-to-air heat exchange up to 70kW. With precise temperature control, this unit can eliminate thermal shock. Have reliable operations with its redundant pumps and dual power feeds and added peace of mind with remote monitoring and communications.

- Product Specifications

- Net Sensible Nominal Capacity kBtuh[kW]*

- 453 kW at 7.2 °F (4.0 °C)

- Nominal Airflow Data Center Air (CFM, m3/h)

- N/A

- Net Sensible Nominal Capacity kBtuh[kW]*

- 453 kW at 7.2 F (4 C): Secondary Circuit flow rate at 110 GPM ( 450 l/m) at 29 psi ( 2 bar) external ΔP

- Input Voltage (V/Phase/Frequency Hz)

- 208 v 60 Hz 3 phase; 480v 60 Hz 3 phase

- Controls and Monitoring

- Color touch screen display

- Agency Approvals

- CE, cULus, RoHS

- Key Components

- Redundant pump design with variable-speed pump controls

- Physical Characteristics

- Weight

- 848 lbs

- Weight

- 385 kgs

- Height

- 74.8 in

- Height

- 1900 mm

- Width

- 23.6 in

- Width

- 600 mm

- Depth

- 41 in

- Depth

- 1043 mm

*To see model-specific downloads, you will need to go to the model-specific product page by selecting the model name in the specifications chart above.