Vertiv™ CoolChip CDU 600

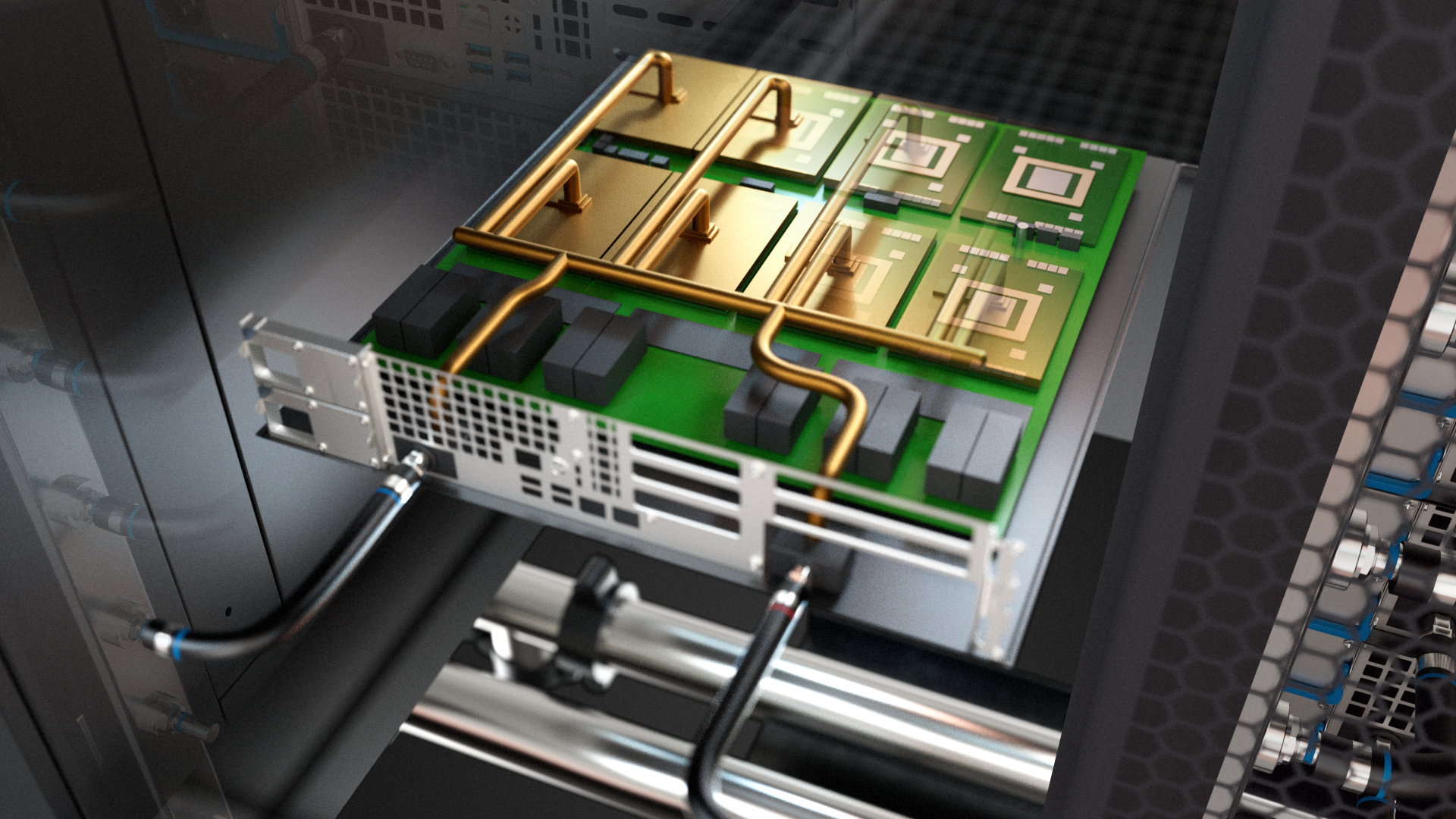

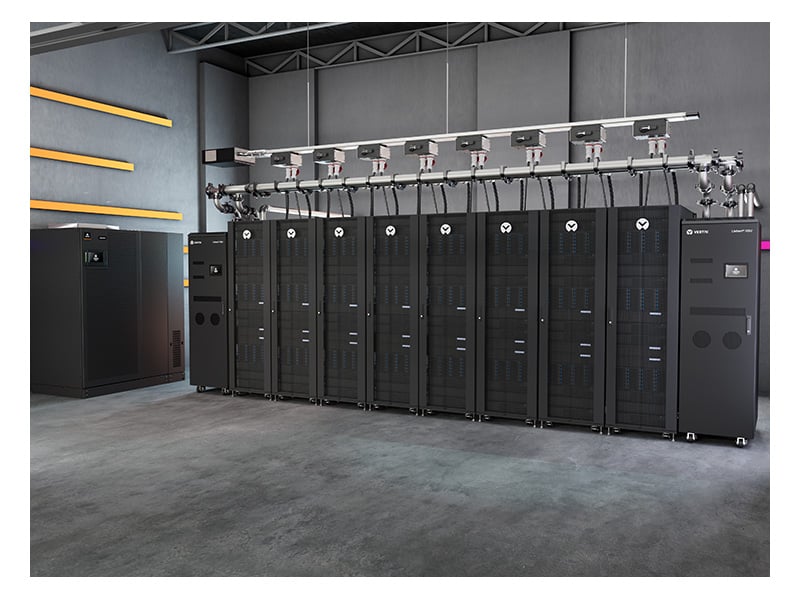

Designed to support liquid cooling within high density environments, the Vertiv™ CoolChip CDU 600 is suitable for direct-to-chip and rear door cooling applications to offer easy, cost-effective deployment in any data center. The Vertiv CoolChip CDU utilizes a liquid-to-liquid heat exchange design, allowing you to tap into the benefits of liquid-cooled servers to more efficiently support higher rack densities while maintaining optimal system conditions.

Zapisano produkt na tablicy użytkownika

Zapisano produkt na tablicy użytkownika, aby móc wrócić do niego w przyszłości. Jeśli nie chcesz tego przedmiotu w zapisanych, można z łatwością usunąć go z tablicy użytkownika.

Zaloguj się lub załóż konto, aby zapisać to na później

- Data Center/Colocation/Hosting

- Education

- Government

- Healthcare

- Retail and Wholesale

Vertiv™ CoolChip CDU 600

Designed to support liquid cooling within high density environments, the Vertiv™ CoolChip CDU 600 is suitable for direct-to-chip and rear door cooling applications to offer easy, cost-effective deployment in any data center. The Vertiv CoolChip CDU utilizes a liquid-to-liquid heat exchange design, allowing you to tap into the benefits of liquid-cooled servers to more efficiently support higher rack densities while maintaining optimal system conditions.

- Data Center/Colocation/Hosting

- Education

- Government

- Healthcare

- Retail and Wholesale

Korzyści

Właściwości

Specyfikacja techniczna

Seamlessly transition to high-efficiency liquid cooling technology with Vertiv™ CoolChip CDU (next generation of Vertiv™ Liebert® XDU family). From hyperscale and colocation environments to edge applications, the Vertiv CoolChip CDU offers flexible deployments for rear door heat exchangers or direct contact liquid cooling. It allows for in-rack, end of row, or perimeter placement options. Easily distribute coolant to efficiently manage power dense deployments with liquid-to-liquid heat exchange up to 100 kW, 450 kW, 600 kW, or 1,350 kW, and liquid-to-air heat exchange up to 70kW. With precise temperature control, this unit can eliminate thermal shock. Have reliable operations with its redundant pumps and dual power feeds and added peace of mind with remote monitoring and communications.

*Aby przejść do materiałów do pobrania dotyczących konkretnych modeli, należy przejść na stronę wybranego modelu produktu, wybierając nazwę w tabeli zawierającej specyfikację techniczną powyżej.