Sistema de arrefecimento Vertiv™ CoolLoop Trim - O refrigerador de arrefecimento livre preparado para IA de 850 a 3000 kW

O sistema de arrefecimento Vertiv™ CoolLoop é a solução de arrefecimento livre, pronta para IA, pronta para densificação e ambientalmente responsável de 850W a 3000 kW. Esta tecnologia de arrefecimento avançada permite que os chillers de arrefecimento livre e denso funcionem eficientemente a temperaturas de água de retorno até 50 °C. Oferece a flexibilidade de escalar de ambientes informáticos tradicionais com fornecimento de água de 20–22 °C para volumes de trabalho de IA mais quentes, mantendo a compacidade, modularidade e precisão. Ao conceber estrategicamente sistemas de arrefecimento para evitar as ineficiências e riscos de projetos estáticos, os proprietários de centros de dados podem adaptar-se perfeitamente às necessidades em evolução da infraestrutura orientada por IA.

Guardar este produto no seu painel

Acabou de guardar este produto no seu painel para o visualizar mais tarde. Pode remover facilmente o item do seu painel de controlo quando já não quiser guardá-lo.

Inicie sessão ou crie uma conta para guardar isto para mais tarde

- Banca, finanças e seguros

- Centro de dados/Colocação/Alojamento

- Governo

- Indústria

Sistema de arrefecimento Vertiv™ CoolLoop Trim - O refrigerador de arrefecimento livre preparado para IA de 850 a 3000 kW

O sistema de arrefecimento Vertiv™ CoolLoop é a solução de arrefecimento livre, pronta para IA, pronta para densificação e ambientalmente responsável de 850W a 3000 kW. Esta tecnologia de arrefecimento avançada permite que os chillers de arrefecimento livre e denso funcionem eficientemente a temperaturas de água de retorno até 50 °C. Oferece a flexibilidade de escalar de ambientes informáticos tradicionais com fornecimento de água de 20–22 °C para volumes de trabalho de IA mais quentes, mantendo a compacidade, modularidade e precisão. Ao conceber estrategicamente sistemas de arrefecimento para evitar as ineficiências e riscos de projetos estáticos, os proprietários de centros de dados podem adaptar-se perfeitamente às necessidades em evolução da infraestrutura orientada por IA.

- Banca, finanças e seguros

- Centro de dados/Colocação/Alojamento

- Governo

- Indústria

Especificações

O sistema de arrefecimento Vertiv™ CoolLoop tem uma capacidade de arrefecimento de 850W a 2600W e até 3000* W em configurações arrefecidas a ar. Foi concebido para ajudar a preparar a sua infraestrutura para o crescimento da densificação impulsionada pelos avanços da IA. Como solução de arrefecimento de próxima geração, o sistema de arrefecimento Vertiv CoolLoop baseia-se não só no arrefecimento líquido, mas também em refrigeradores híbridos e de ar capazes de gerir temperaturas de fluido imprevisíveis.

|

Vertiv™ CoolLoop Trim Cooler LVZ230

|

||||

|---|---|---|---|---|

| 3100 kW | Freecooling | 113.5 in | 92.52 in | 635.81 in |

| Ver mais informações sobre o produto | ||||

|

Vertiv™ CoolLoop Trim Cooler LVZ170

|

||||

| 2700 kW | Freecooling | 113.5 in | 92.52 in | 535.69 in |

| Ver mais informações sobre o produto | ||||

|

Vertiv™ CoolLoop Trim Cooler LVZ140

|

||||

| 2110 kW | Freecooling | 113.5 in | 92.52 in | 435.58 in |

| Ver mais informações sobre o produto | ||||

|

Vertiv™ CoolLoop Trim Cooler LVZ090

|

||||

| 1540 kW | Freecooling | 113.5 in | 92.52 in | 385.79 in |

| Ver mais informações sobre o produto |

Vantagens

- ARREFECIMENTO LÍQUIDO, FÁBRICAS AI-READY: Suporta avanços de densificação orientados por IA combinando capacidade de arrefecimento de ar e líquido.

- EFICIÊNCIA MÁXIMA DE ARREFECIMENTO LIVRE: Lida com picos operacionais, minimizando o consumo de energia. Obtenha até 1,087 pPUE, com um aumento de eficiência de quase 70%* reduzindo as emissões indiretas.

- SEM CONSUMO DE ÁGUA: Uma operação a seco reduz a complexidade operacional, ajuda a eliminar o desperdício de água e remove a dependência de abastecimentos de água ou infraestrutura de tratamento.

- ARREFECIMENTO ECO-CONSCIENTE: Em conformidade com as principais proibições atuais e futuras e os regulamentos da UE relativos a gases fluorados durante os próximos anos, reduzindo as emissões diretas de CO2e, ao mesmo tempo que garante a máxima eficiência sazonal, especialmente em carga parcial.

- EFICIENTE ESPACIAL: Não é necessária ocupação adicional do espaço no tejadilho. Ganho líquido de mais de 40% da capacidade de arrefecimento sem aumentar a pegada global.

- FLEXIBILIDADE GLOBAL: Adequado para centros de dados em vários climas em todo o mundo.

*Carga de TI arrefecida a ar de 10 MW a funcionar a uma capacidade de 80% com temperaturas de água a 20 °C, atingindo um pPUE de 1,15 com refrigeradores padrão. A uma temperatura mais elevada de 35 °C com o refrigerador de corte Vertiv™ CoolLoop a alcançar um pPUE mais elevado estimado em 1,087 e um aumento de eficiência de quase 70%.

Características

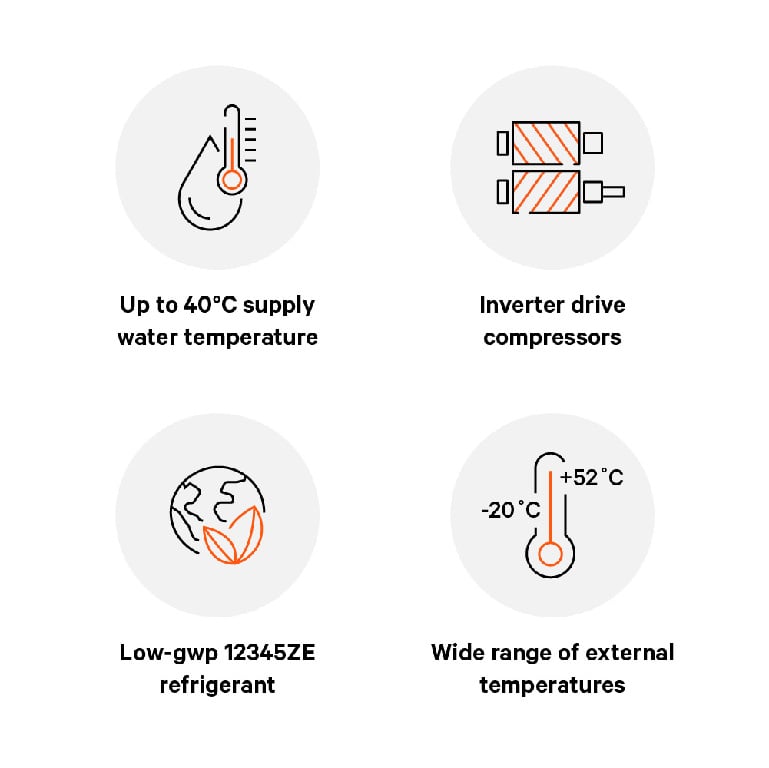

- INTEGRAÇÃO DE ARREFECIMENTO LÍQUIDO SEM LAMAS: Até 40 °C de temperatura da água de alimentação, permitindo que as placas frias funcionem a 45 °C; até 50 °C no retorno. Acoplamento fácil com Vertiv™ CoolChip CDU e Vertiv™ Soluções de água arrefecida.

- OTIMIZAÇÃO DE ARREFECIMENTO LIVRE: Bobinas de arrefecimento livre concebidas para temperaturas ambiente elevadas que incorporam permutadores de calor de microcanal para transferência de calor superior.

- TECNOLOGIA MOVIDA PELO INVERSOR: Compressores, ventiladores EC e bombas permitem que o sistema funcione de forma eficiente mesmo durante picos operacionais, modulando a velocidade do compressor de acordo com a procura.

- REFRIGERANTES: GWP muito baixo R1234ze líquido de refrigeração com GWP = 7 de acordo com IPCC AR4.

- DESIGN DE POUPANÇA DE ESPAÇO: Até quase 3 MW** de capacidade de arrefecimento numa única estrutura compacta com filtros harmónicos ativos no interior do painel elétrico.

- ARREFEÇA EM TODOS OS LUGARES: Disponível numa vasta gama de temperaturas ambiente de -20 °C a mais de 52 °C.

**Na configuração arrefecida a ar

*Para ver transferências específicas do modelo, terá de ir para a página de produto específica do modelo, selecionando o nome do modelo na tabela de especificações acima.