Continuity of the power supply inside a data center has always been (and probably always will be) one of the trickiest aspects of creating an infrastructure. That is why this issue has often been the subject of in-depth studies, proposals, and discussions.

Continuity of the power supply inside a data center has always been (and probably always will be) one of the trickiest aspects of creating an infrastructure. That is why this issue has often been the subject of in-depth studies, proposals, and discussions.

Prompted by what appears to be a new trend, I would like to briefly present the solution that is capable of providing limited autonomy, compared with what has been used up to now. This can be achieved by adopting modular high-power static UPS’s combined with back-up energy sources, maintenance-free lead batteries.

The first aspect to address is the question of the power levels involved.

Without going into a long discussion about trends in the uninterruptible power supplies that data centers want, it is fair to say that today, the data center world is still faced with high power density values per rack (20 – 30 kW per rack in high-density areas), which require large infrastructures to be designed. So, to take a benchmark, for data centers with rooms on the order of one thousand square meters, the nominal power rating of at least 1 MW for a single static UPS has become a standard value over the years.

However, one aspect that is becoming very challenging is the constantly evolving software environment, which is dynamic, inserted within an infrastructure which, at the same time and by definition, makes the quality of being static one of its main characteristics. The challenge, then, is to find a way to make these two aspects coexist, keeping all the requirements related to security, reliability, and maintainability unchanged.

This is the context in which the choice of a modular UPS must fit; a UPS be able to supply a high active power (> MW) in its maximum available configuration. The high rated power allows centralized equipment solutions to be adopted, which facilitates all aspects related to monitoring and operation, unlike a distributed solution, which turns out to be more complicated.

Moreover, if the single module is capable of supplying sufficient power (200-400 kW), the modular solution provides UPSs with much higher rated power than what is available with traditional monolithic solutions.

Finally, modularity lets you optimize the initial capex and respond in a truly dynamic manner (only when the need actually arises) to the many plant requirements, thereby supporting the business.

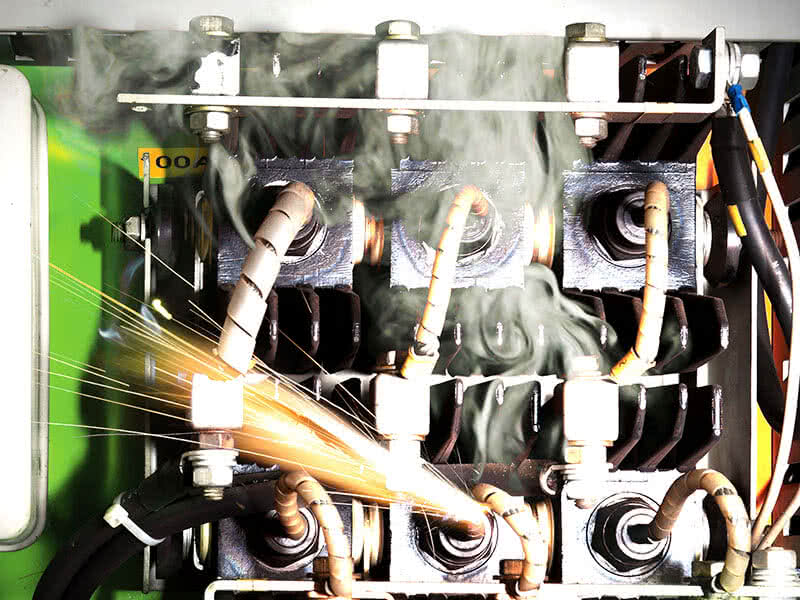

For the same type of accumulator and equal autonomy, when the uninterrupted power is measured in MW, you have non-standard battery installations.

A radically limited autonomy, approximately one minute under nominal conditions, has a significantly lower cost and reduces the complexity of the installation.

On the other hand, however, people who make this type of choice must be aware of its consequences. It is clear that this solution can only be adopted in situations where the sole aim is to cope with problems related to micro-outages, or where a standby generator is sure to be available very quickly (start-up and changeover within 20 to 30 seconds).

When the back-up source provides very short autonomy, its availability and efficiency become even more important, if that is possible.

That is why advanced battery monitoring systems are also used in this type of installation. These are capable of measuring the voltage, temperature, and internal resistance of every single monobloc.

The continuous monitoring of these parameters via appropriate dedicated software provides a way of checking on their state and the behaviour of the accumulators in every operating situation. It also lets you determine, to a certain extent, when battery performance eventually starts to flag due to normal wear. This can be done by comparing the actual measurements taken in the field to the initial values measured at the time of installation and to the manufacturer’s specifications. This information lets you decide when the installed batteries should be replaced, before the decline in their performance starts to create a risk to the users being supplied.

Obviously, monitoring systems like this can also notify you of any operating errors in real time, by generating signals and/or alarms according to the type of situation.

Will this type of UPS solution become standard in the near future?

What is your experience?