Together, Albér™ BCTI and Albér™ UXIME Simplify Capacity Testing and Business Continuity

North American utilities provide a continuous flow of power to businesses and consumers. As a consequence, ensuring business continuity is mission-critical and protects the customer experience. Utilities rely on Uninterruptible Power Supplies (UPSs) to provide essential backup power when primary power sources are unavailable. To ensure they’re always ready to provide emergency power, bulk power system owners, operators and users must meet industry maintenance and testing requirements. One important one is the North American Electric Reliability Corporation (NERC) Reliability Standard PRC-005-6.

To date, utilities have been able to leverage automated solutions to test battery internal resistance. However, testing battery capacity to meet PRC-005-6 requirements is much more cumbersome. Utilities must either rent equipment and perform these tests manually or hire third-party contractors to perform capacity tests and routine maintenance. It typically takes two technicians to perform the tests, which can last one to two days, on a prescheduled basis, ranging from once a year to every five years.

Gain a Fully Integrated Battery Testing Solution for NERC Compliance

Now, it’s possible to automate both internal resistance and capacity testing with just one integrated solution, eliminating the need to schedule contractors, interact with staff onsite and pay ongoing equipment and service fees. Vertiv is proud to announce the launch of Albér™ Battery Capacity Testing Interface (BCTI), which provides automated load testing capacity and integrates seamlessly with Albér™ Universal Xplorer Industrial Monitor (UXIME) solution.

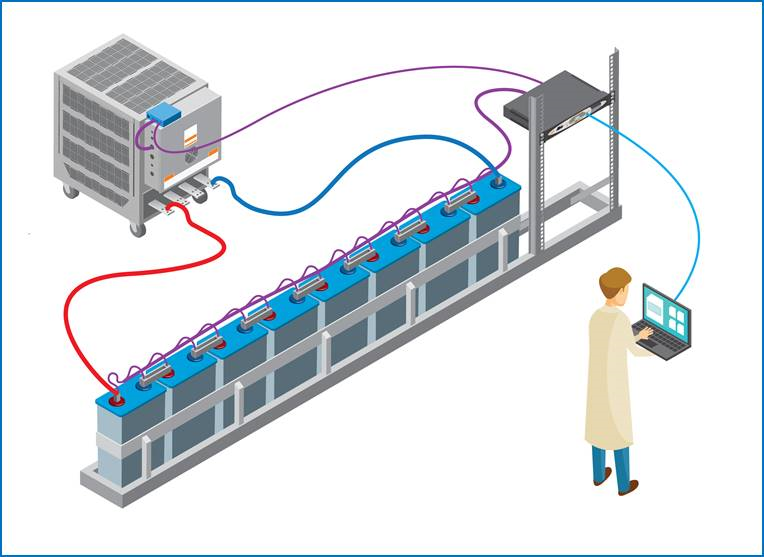

Albér BCTI provides an interface to Alber CLU for testing setup and load control during capacity testing. Albér UXIME, the stationary battery monitor, collects, processes and reports data. Since Albér UXIME is already attached to the battery, all a user needs to do to run a capacity test is connect Albér BCTI hardware to Albér UXIME and begin the test.

Benefits of Automating Battery Capacity Testing

So, what could automating battery capacity testing do for your utility? Benefits include:

Avoiding costly outages: With automated testing, utility teams can perform testing whenever necessary – not just on a scheduled basis. That means teams can develop real-time insights into battery capacity, use test reports to support audits and avoid disabling outages. For utilities, ending outages due to backup power supply failures prevents costly fines and penalties.

Saving money and time: While legacy capacity testing processes require third-party technicians and equipment, tests can be automated moving forward with Albér™ BCTI and Albér™ UXIME. That adds up to labor and equipment savings across every test, battery, site and network of facilities, which can be considerable. As just one example, technicians no longer need to attach sense leads to each cells for each string tested, which is extremely time-consuming and increases safety risks. As a result, testing processes are streamlined from one to two days to under 20 minutes with Albér™ BCTI and Albér™ UXIME, simplifying testing operations.

Scaling testing operations: Automation enables utilities to easily schedule and scale testing across all of their locations. Since tests are fast and seamless, they should also be easier to schedule in a manner that’s less interruptive of daily operations than interfacing with third-party technicians who perform testing services.

Managing battery lifespan proactively: Conducting regular capacity testing of batteries is the only way to determine batteries’ true health and lifespan. By so doing, teams can actively manage out failing batteries. They also can change out individual cells that are failing to extend battery lifespans, avoiding unnecessary and costly replacements. Finally, teams don’t need to overprovision batteries because they accurately understand current capacity.

Improving technician safety: Since capacity tests can now be automated, technicians don’t need to handle battery connections. That eliminates the risk that technicians will touch live voltage, which can result in harm if staff aren’t wearing the proper personal protective equipment (PPE).

Enhancing data consistency: Manual testing approaches may vary across technicians. Automating capacity testing provide highly accurate, consistent data that can be used to establish battery performance baselines and measure changes over time.

Conclusion

Albér™ BCTI and Albér™ UXIME provide a fully automated solution that now offers both internal resistance and capacity battery testing for utility and industrial applications. Standard configurations are specifically designed for utility substations’ 120V and 480V applications. As such, the device can be used to meet NERC PRC-005-6 requirements and IEEE 450 recommended practices for battery maintenance and monitoring.

Albér BCTI enables constant current and power testing, by automating load control. Albér™ UXIME, the stationary battery monitor, collects, processes and reports data. Together, the integrated solution provides real-time data capture of all key variables teams need to measure battery performance.

Yes, there is a simpler way to ensure NERC compliance, while achieving a host of other business gains.