Vertiv™ CoolLoop Trim Cooler - Le groupe froid freecooling prêt pour l’IA de 850 à 3 000 kW

Le Vertiv™ CoolLoop Trim Cooler est la solution de refroidissement freecooling de 850W à 3 000 kW, prête pour l’IA et la densification, et respectueuse de l’environnement. Cette technologie de refroidissement avancée permet aux groupes de production d’eau glacée freecooling denses de fonctionner efficacement à des températures d’eau de retour allant jusqu’à 50 °C. Elle offre la flexibilité d’évoluer des environnements informatiques traditionnels avec une eau fournie de 20 à 22 °C, vers les charges de travail d’IA plus chaudes, tout en maintenant la compacité, la modularité et la précision. En concevant stratégiquement des systèmes de refroidissement pour éviter les inefficacités et les risques des conceptions statiques, les propriétaires de data centers peuvent s’adapter de manière transparente aux besoins évolutifs de l’infrastructure pilotée par l’IA.

Produit enregistré dans votre tableau de bord

Vous venez d’enregistrer ce produit dans votre tableau de bord afin de le consulter ultérieurement. Vous pourrez ensuite facilement le supprimer quand vous n’en aurez plus besoin.

Veuillez vous connecter ou créer un compte pour enregistrer ce contenu

- Banque, finance et assurance

- Datacenter / Colocation / Hébergement

- Administration

- Fabrication

Vertiv™ CoolLoop Trim Cooler - Le groupe froid freecooling prêt pour l’IA de 850 à 3 000 kW

Le Vertiv™ CoolLoop Trim Cooler est la solution de refroidissement freecooling de 850W à 3 000 kW, prête pour l’IA et la densification, et respectueuse de l’environnement. Cette technologie de refroidissement avancée permet aux groupes de production d’eau glacée freecooling denses de fonctionner efficacement à des températures d’eau de retour allant jusqu’à 50 °C. Elle offre la flexibilité d’évoluer des environnements informatiques traditionnels avec une eau fournie de 20 à 22 °C, vers les charges de travail d’IA plus chaudes, tout en maintenant la compacité, la modularité et la précision. En concevant stratégiquement des systèmes de refroidissement pour éviter les inefficacités et les risques des conceptions statiques, les propriétaires de data centers peuvent s’adapter de manière transparente aux besoins évolutifs de l’infrastructure pilotée par l’IA.

- Banque, finance et assurance

- Datacenter / Colocation / Hébergement

- Administration

- Fabrication

Caractéristiques

Le Vertiv™ CoolLoop Trim Cooler dispose d’une puissance frigorifique allant de 850 kW à 2 600 kW, et jusqu’à 3 000 kW* dans les configurations refroidies par air. Il est conçu pour aider à préparer votre infrastructure à une densification croissante générée par les avancées de l’IA. En tant que solution de refroidissement de nouvelle génération, le Vertiv CoolLoop Trim Cooler s’appuie non seulement sur le refroidissement liquide, mais également sur des groupes froids à air et hybrides capables de gérer des températures de fluide imprévisibles.

|

Vertiv™ CoolLoop Trim Cooler LVZ230

|

||||

|---|---|---|---|---|

| 3100 kW | Freecooling | 113.5 in | 92.52 in | 635.81 in |

| Voir plus d’informations produits | ||||

|

Vertiv™ CoolLoop Trim Cooler LVZ170

|

||||

| 2700 kW | Freecooling | 113.5 in | 92.52 in | 535.69 in |

| Voir plus d’informations produits | ||||

|

Vertiv™ CoolLoop Trim Cooler LVZ140

|

||||

| 2110 kW | Freecooling | 113.5 in | 92.52 in | 435.58 in |

| Voir plus d’informations produits | ||||

|

Vertiv™ CoolLoop Trim Cooler LVZ090

|

||||

| 1540 kW | Freecooling | 113.5 in | 92.52 in | 385.79 in |

| Voir plus d’informations produits |

Avantages

- REFROIDISSEMENT LIQUIDE, PRÊT POUR LES USINES IA : Prend en charge les avancées en matière de densification générée par l’IA, combinant la puissance du refroidissement liquide et par air.

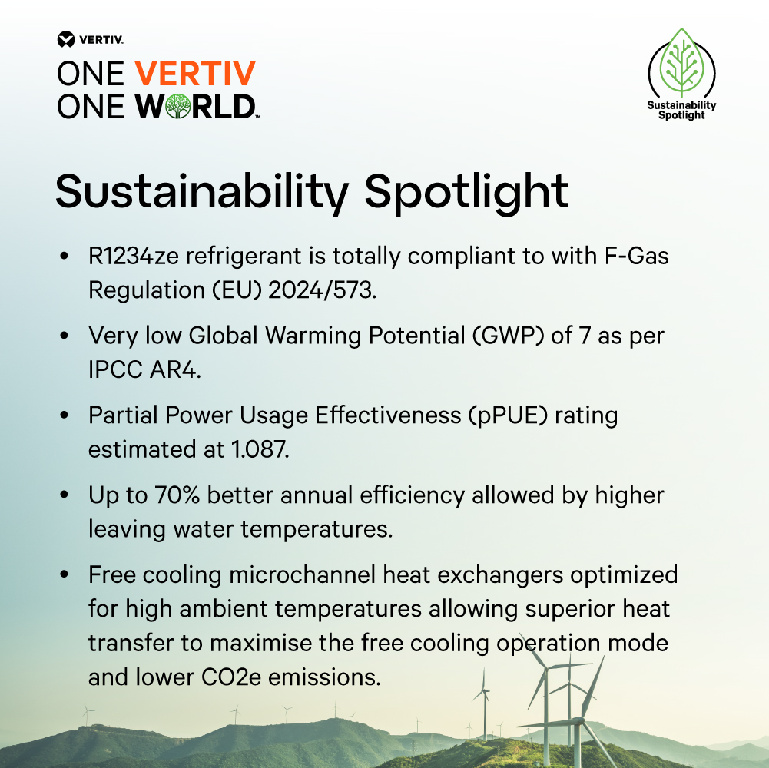

- EFFICACITÉ OPTIMISÉE DU FREECOOLING : Gère les pics de fonctionnement tout en minimisant la consommation électrique. Atteint jusqu’à 1,087 pPUE, avec une augmentation d’efficacité de près de 70 %* réduisant les émissions indirectes.

- PAS DE CONSOMMATION D’EAU : Un fonctionnement à sec réduit la complexité opérationnelle, aide à éliminer le gaspillage d’eau et supprime la dépendance à l’alimentation en eau ou l’infrastructure de traitement.

- REFROIDISSEMENT ÉCO-RESPONSABLE : Conforme aux principales restrictions actuelles et futures et aux réglementations F-Gas de l’UE pour les années à venir, réduisant les émissions directes de CO2e tout en permettant une efficacité saisonnière optimale, en particulier à charge partielle.

- ENCOMBREMENT OPTIMISÉ : Aucune occupation d'espace supplémentaire sur le toit n'est requise. Gain net de plus de 40 % de puissance frigorifique sans augmenter l’encombrement global.

- FLEXIBILITÉ MONDIALE : Convient aux data centers dans divers climats à travers le monde.

*Charge informatique refroidie par air de 10 MW fonctionnant à 80 % de capacité avec des températures d’eau à 20 °C, atteignant un pPUE de 1,15 avec des groupes de production d’eau glacée standard. À une température supérieure de 35 °C, avec Vertiv™ CoolLoop Trim Cooler atteignant un pPUE plus élevé estimé à 1,087 et une augmentation de l’efficacité de près de 70 %.

Caractéristiques

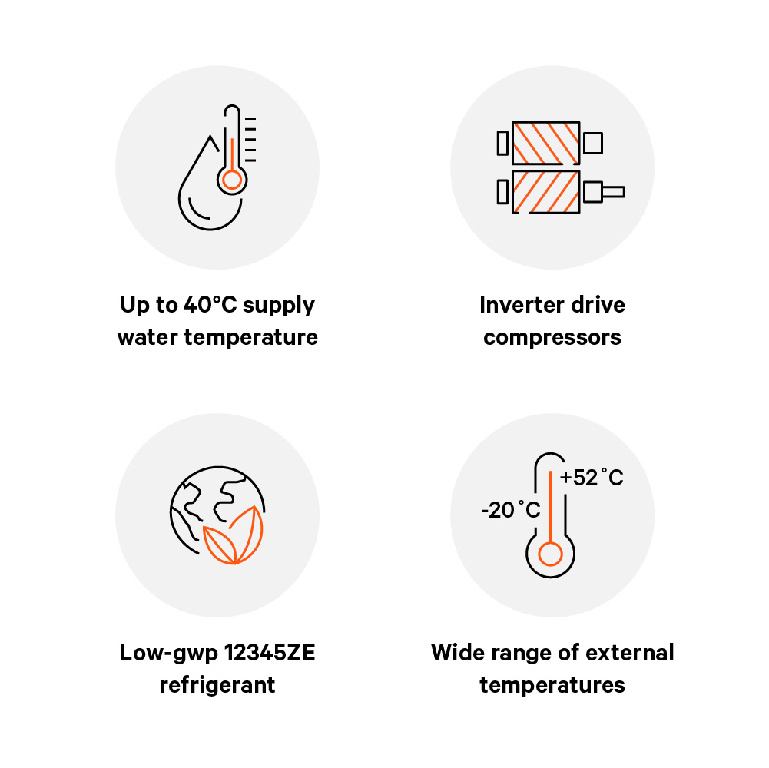

- INTÉGRATION TRANSPARENTE DU REFROIDISSEMENT LIQUIDE : Jusqu’à 40 °C de température de l’eau fournie permettant aux plaques froides de fonctionner à 45 °C ; jusqu’à 50 °C en retour. Couplage facile avec les solutions Vertiv™ CoolChip CDU et Vertiv™ Chilled Water.

- OPTIMISATION DU FREECOOLING : Batteries de freecooling conçues pour les températures ambiantes élevées intégrant des échangeurs thermiques à micro canaux pour un transfert de chaleur supérieur.

- TECHNOLOGIE PILOTÉE PAR INVERTER : Les compresseurs, les ventilateurs EC et les pompes permettent au système de fonctionner efficacement, même pendant les pics d’exploitation, en modulant la vitesse du compresseur en fonction de la demande.

- RÉFRIGÉRANTS : Réfrigérant R1234ze à très faible PRG avec PRG = 7 conformément au GIEC AR4.

- CONCEPTION COMPACTE : Jusqu’à près de 3 MW** de puissance frigorifique dans un seul châssis compact avec filtres harmoniques actifs à l’intérieur du tableau électrique.

- REFROIDIR PARTOUT : Disponible dans une large plage de températures ambiantes de -20 °C à plus de 52 °C.

**Dans la configuration refroidie par air

* Pour accéder aux téléchargements de modèles spécifiques, rendez-vous sur la page du produit en question en sélectionnant le nom de modèle dans le tableau de spécification plus haut.