How a DX Cooling System Works

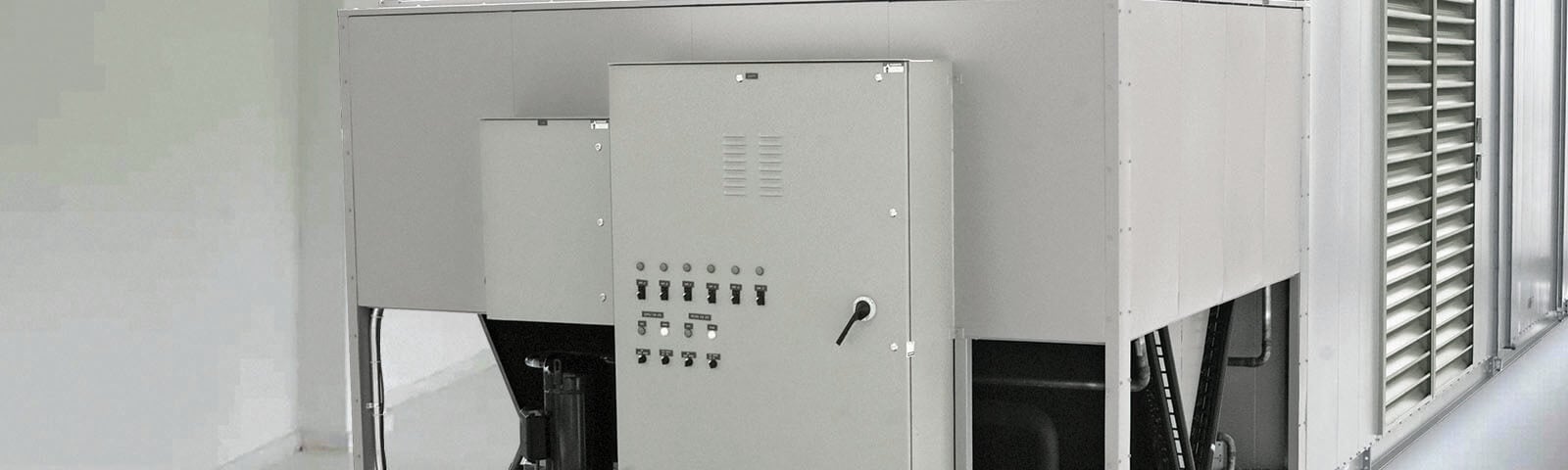

A direct expansion or DX cooling system is a type of air-conditioning system that removes heat from a space through evaporation and condensation of a refrigerant. The refrigerant absorbs the heat in the air, such as the heat generated by IT equipment in a network closet or other IT space, and then ultimately rejects the heat outdoors. This is possible because the refrigerant boils below room temperature, and is condensed back to a liquid by transferring the heat to outdoor air or water through a heat exchanger

In a DX cooling system, the evaporator is placed inside the space to be cooled. The refrigerant enters the DX cooling coils, where it absorbs the heat from the air and transforms to a gas. The refrigerant then moves into the condenser located outside, where the heat is released. An expansion valve exists between the evaporator and the condenser to help facilitate the changes in the pressure and temperature of the refrigerant as it moves through this cooling process. A compressor drives the refrigerant through its journey, and the entire DX cooling system offers a closed loop solution.

Advantages and Disadvantages of DX Cooling in an IT Environment

Compared to chilled water and other types of cooling systems commonly deployed in data centers or other IT spaces, DX cooling offers more flexibility and can operate at lower costs if the number of heat exchanges is minimized. Chilled water systems may be built out in larger blocks than a DX system, reducing the flexibly to build as you go. In addition, DX cooling can eliminate the need to introduce water into IT spaces filled with sensitive equipment, which is a major plus for many data center managers. Multiple DX systems can offer redundancy, compared to a chilled water system if there is only one chiller serving the cooling loop.

However, the bigger a data center space grows, the less ideal a DX cooling system becomes. For one thing, long piping routes can be a challenging aspect of installing a DX cooling system in a large space. Running multiple refrigerant lines can become more expensive than running fewer chiller water piping loops.

Recent Innovations in DX Cooling

Recent innovations are changing the efficiency and scalability of DX systems and causing many data center managers to give them a second look when it comes to choosing the right cooling strategy for their data center or IT space. The most notable advances in DX cooling technology include:

- Variable technologies. Newer DX cooling system models incorporate multiple variable technologies for components ranging from compressors to condenser fans, evaporator fans, pumps, and expansion valves. These technologies respond to and match changes in room load. In other words, the cooling system components do not always operate at full capacity, but instead use only the energy needed to manage the heat in the room at any given time.

- Pumped refrigeration economization. From an equipment design perspective, even an electronically commutated (EC) fan will help in power saving to some extent. But the compressor power contributes to almost 50-70% of the total power consumed by any DX unit. Pumped refrigerant systems allow the compressor to remain off or operate less during lower outdoor ambient temperatures by switching to the economization cycle. In this cycle, sometimes called free cooling, outdoor ambient air is used to cool the refrigerant directly to the needed temperature rather than using the compressor and expansion valve to do so. The refrigerant pump can operate at nearly 1% of the power required to operate a compressor in normal DX cooling mode. During full utilization of economization cycle, the cooling power usage efficiency or PUE of the cooling system can be as low as 1.05.

- Smart controls. The better the controls are on a DX cooling system, the less margin of error you need, and the more efficiently you can run your system. Best-in-class DX cooling relies on advanced controls to precisely measure data center IT load and continuously adapt to the most efficient operating mode. This helps control costs by ensuring cooling system reliability without any overcooling.

Together, variable technologies, economization options, and the right controls can make a DX cooling strategy an effective option in almost any IT environment no matter the size.

DX Cooling Solutions Available From Vertiv

Vertiv specializes in a wide range of precision cooling solutions geared toward meeting size, location, and business specifications within mission-critical facilities. Our portfolio of DX cooling products includes options designed to support a vast range of applications, from small computer rooms to enterprise data centers. Some of our most popular DX cooling solutions include:

- Vertiv™ Liebert® DSE™ Free-Cooling Economization System. This DX cooling system, using the Vertiv™ Liebert® iCOM™ controls, captures every available economization hour with smooth, automated transitions. The system provides split-system refrigerant economization with more than two dozen configurations for airflow, form factor, and capacity. Additionally, it can be deployed in perimeter, gallery, and full-face discharge applications for raised floor and non-raised floor data centers. It is also available as a self-contained, factory-piped, factory-wired configurations that is installed completely outdoors, requiring no field installation of refrigerant piping.

- Vertiv™ Liebert® PDX Compact DX Cooling System. Designed for small spaces, this DX cooling system offers the industry’s highest capacity per footprint. It is highly configurable while offering full and partial free cooling. The Liebert® PDX has unique, floor-level air discharge that reduces the mixing of hot and cold air to improve efficiency. Downflow models provide front, left-side and right-side discharge and upflow models provide front and rear return options The Liebert® EconoPhaseTM pumped refrigerant economizer is compatible with the Liebert PDX indoor unit and the Liebert MC condenser to improve overall system efficiency.

- Vertiv™ Liebert® CRV Row-Based Cooling. The Liebert® CRV is a precision data center cooling solution, integrated within a row of data center racks. It is designed to address some of the major challenges seen in high-density applications. With adjustable airflow baffles and controls that independently manage airflow and temperature, the Liebert CRV can precisely deliver highly efficient cooling in the row where it is needed. The system is available in multiple options, providing flexibility for any installation. Variable capacity fans and compressors enable energy savings since the cooling system operates to meet the load in the IT space.

Visit the Vertiv website to learn more about thermal management solutions including DX cooling solutions for all your IT spaces.