Market research released earlier this year by OMDIA opened some eyes across the data center industry. The firm surveyed 228 data center professionals with decision-making responsibility for their organization’s use of modular prefabricated data center solutions.

That research, Addressing Today’s Data Center Construction Challenges, found that not only is use of prefab data center modules greater than many expected – more than half (52%) of participants had already deployed these integrated solutions – but that usage is likely to grow significantly in the coming years. Ninety-nine percent said prefabricated modular data centers are part of their future strategy and 93% said they would use prefabricated modular data centers as their default construction process.

Benefits of Prefabricated Modular Data Centers

While those results signal a dramatic uptick in use of integrated design and construction processes, the more you learn about prefabricated modular data centers, the less surprising the adoption statistics become.

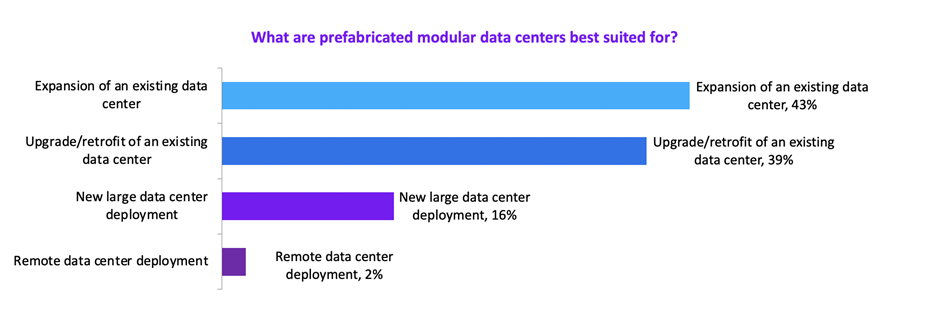

Prefabricated modular solutions allow operators to add capacity faster than is typically possible using traditional approaches and speed-of-deployment has become key to keeping pace with the growing demand for data center capacity. In its research, OMDIA asked decision makers what they felt prefabricated modular data centers were best suited for and the top answer was data center expansions, followed by upgrades/retrofits, and new data center deployments.

Whether expanding or upgrading an existing facility or building a new one, prefab data center solutions allow owners and operators to compress their timelines and achieve their goals faster. Prefabrication enables streamlined processes that are performed in a controlled environment by specialists. For new capacity, this eliminates tasks such as sourcing system components, coordinating delivery, and on-site integration and testing. Instead of having to devote time and resources to managing those activities, a fully integrated and tested system arrives on site ready for connection and startup.

As projects become more complex, the time savings enabled by prefabrication become greater. In a traditional or “stick-build” data center construction process, for example, a project will go through distinct engineering, site prep, construction, installation and startup phases, and developers deal with a changing team of contractors and vendors throughout the process. With a prefabricated data center solution, the ability to compress these processes under the management of a single partner can shorten the timeline for bringing a new facility online by up to 30%.

This speed-to-market enables faster scalability, which was the top benefit of prefabricated and modular data center solutions identified in the OMDIA research. Because capacity is added in modules, it becomes easier and faster to scale. Shortening the timeline for expansion can also reduce the need to overbuild based on future demand, lowering CAPEX costs.

Another benefit of prefabricated modular data center solutions is their ability to integrate new technologies into design and fabrication processes. Specifically, the research highlighted a strong connection between prefabricated data center solutions and liquid cooling. Twenty-three percent of participants said that liquid cooling is the optimal cooling approach for modular data centers and an additional 39% chose hybrid air/liquid cooling as the optimal approach.

This is proving particularly true for high-capacity regional data centers. Sometimes mistakenly referred to as containerized data centers, these solutions are most effective when fabricated using purpose-built outdoor enclosures rather than repurposed shipping containers.

Finally, the OMDIA research points to the ability of prefabricated modular data centers to meet operators’ desire to increase efficiency and reduce emissions. Twenty-five percent of participants said sustainability is the single most important factor affecting data center decisions today, and an additional 59% said it was a top-five consideration. By designing and fabricating for efficiency and enabling the use of newer technologies such as liquid cooling and intelligent power systems, prefabricated modular data centers can achieve PUE levels well below the current industry average, resulting in a lower carbon footprint.

Types of Prefabricated Modular Data Centers Solutions

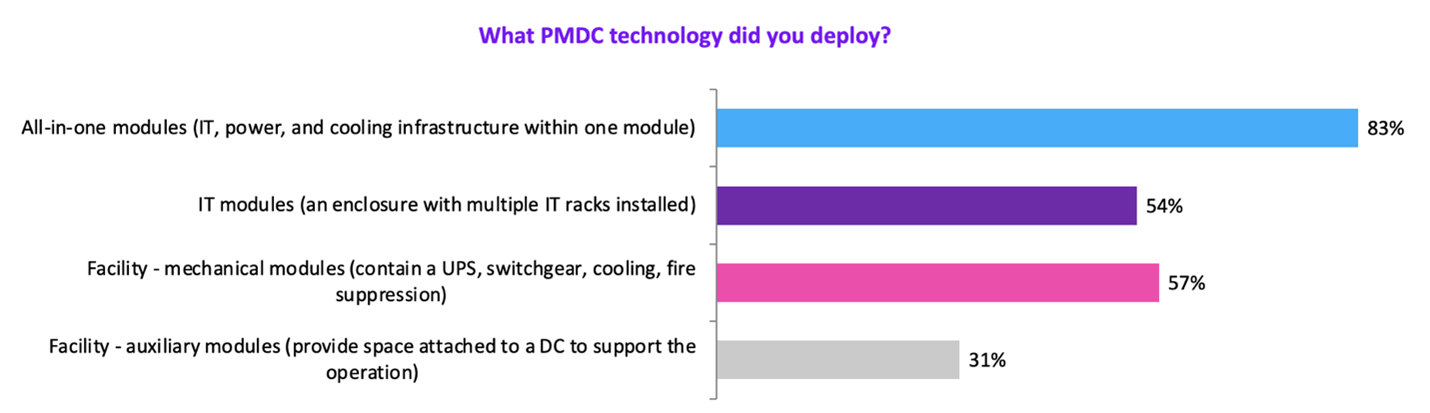

Prefabricated modular data center solutions can be broadly classified into two categories: all-in-one solutions and system-level modules.

“All-in-one” solutions represent complete solutions that include the facility structure, all infrastructure and support systems, and IT systems. These solutions are generally used for new data center deployments, including both large free-standing data centers and edge sites. According to the OMDIA research, all-in-one solutions have been deployed by a higher percentage of participating organizations than other types of modular solutions. However, they comprise only a fraction of the total number of modules deployed.

System-level modular solutions include IT modules that add compute capacity, auxiliary modules that expand physical space, and facility mechanical modules designed to upgrade or expand existing power and cooling systems.

Facility mechanical modules are the most commonly deployed system-level modules and consist of a complete power or cooling system that has been fully integrated and tested off site and arrives ready for fast installation. Power modules can be delivered as a complete power room or as an open, skid-mounted system. Cooling skids are custom designed to provide additional capacity to an existing site or to upgrade an existing system to support increased capacity and improved efficiency.

Vertiv Prefabricated Modular Data Center Solutions

Vertiv offers prefabricated modular data center solutions that leverage our deep data center expertise; full portfolio of infrastructure technologies; and global network of design, project management, and technical specialists. Our solutions include:

-

Large prefabricated modular data centers, such as this lab developed for Orange. From project conception through startup, we manage every phase of the project, delivering prefabricated modules to the site that are then assembled on site using processes that are faster, safer, and require less labor than traditional stick-build processes.

-

Compact, fully-contained edge data centers enabled by our Vertiv™ SmartMod™ and Vertiv™ SmartRow™ platforms. Whether you’re adding edge sites within existing facilities or in remote locations, these solutions speed deployment while delivering availability tailored to your requirements.

-

High-density, power modules built around market-leading technology. These systems enable capacity expansions or system upgrades with limited site work. They arrive on site, fully integrated and tested to support near plug-and-play deployments.

-

Customizable cooling modules that enable cooling-constrained sites to increase IT capacity, older data centers to improve their PUE with more efficient technologies, and support for high-density racks or zones.

Learn More

To learn more about the evolution of prefabricated modular data centers and how operators are using them today, view the webcast, Addressing Today’s Data Center Construction Challenges or visit our prefabricated modular solutions web page.