What happens when rack power climbs past the comfort zone of conventional air cooling? A behind-the-rack solution is quietly taking the lead.

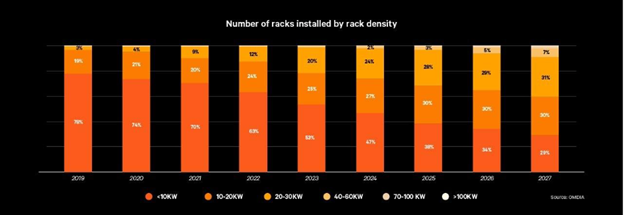

More computing in less space demands a new level of data center cooling. As deployments above 10 kilowatts (kW) continue to grow (see Figure 1), operators are approaching a critical threshold; around 20 kW, conventional air cooling begins to reach its practical limits. Supporting high-density racks requires more efficient thermal strategies—liquid cooling or a hybrid of liquid and air cooling is a key part of that shift.

Figure 1. Graph showing the number of racks installed by rack density over the years. According to Omdia, racks below 10 kW comprised 47% of installed capacity in 2024. By 2025, that dropped to 38%. Meanwhile, the share of 10–20 kW racks rose from 27% to 30%, and 20–30 kW racks climbed from 24% to 28%. Source: Vertiv™ AI Hub

But liquid cooling adoption can be complex for some facilities, with factors like plumbing, facility design, and varied heat loads shaping how quickly operators can move. This is where rear door heat exchangers (RDHxs) take the lead. They enable operators to manage rising rack densities without waiting for improved chilled water systems or major infrastructure work. They fit the moment: fast to deploy, tightly focused, and engineered for precision.

Considerations in liquid cooling adoption

Liquid cooling adoption often involves building out primary and secondary loops. The process can be complex for some data center architectures, requiring specialized equipment, wetted material compliance, plumbing, and ongoing upkeep. Even when chilled water is available, connecting multiple racks isn’t just a technical challenge—it’s a logistical one. Heat loads vary across facilities, and uniform cooling is difficult to achieve.

For many operators, especially those working in edge environments or retrofitting existing spaces, the timeline and investment required for complete liquid cooling systems are too steep. In these cases, RDHxs can provide a practical, fast-to-deploy solution for managing rising rack densities.

What are rear-door heat exchangers (RDHxs)?

RDHx (see Figure 2) is a type of air-assisted liquid cooling system that uses liquid's high thermal transfer properties without requiring a liquid-cooled server. Fluid flow control is adjusted based on the return water temperature using a modulating valve for efficiency. These units offer remote access, alarms, and system status updates for enhanced monitoring and control. Passive or active heat exchangers replace the rear door of the IT equipment rack with a liquid heat exchanger.

Figure 2. A 3D rendering of how RDHx systems work, showing how the exhaust (hot) air is cooled before it passes through the rear door of the rack.

Types of RDHxs

Passive RDHx units rely entirely on the airflow generated by the server’s internal fans. Hot exhaust air exits the rack and passes through a heat exchanger mounted on the rear door. Chilled water circulating through the internal coils absorbs the heat from the air.

Active RDHx (see Figure 3) builds on the same rear-door design but adds integrated fans to assist in pulling exhaust air through the heat exchanger. The embedded fans operate at variable speeds to maintain consistent air pressure and temperature, improving responsiveness to localized hotspots or shifting rack loads.

Figure 3. A diagram illustrating RDHx’s heat dissipation process, where exhaust air is cooled by passing through a liquid-filled coil, transferring heat to chilled water before being recirculated back into the data center.

How RDHx cooling enables AI growth

Scalable cooling without infrastructure overhaul

RDHx systems enable operators to scale high-density computing without significant infrastructural overhauls. Their modular design allows installation in standard racks and operation without facility water, making them suitable for legacy environments. RDHx cooling reduces strain on room-level systems as rack power climbs, helping maintain thermal stability even as computing density increases.

Flexible deployment and minimal disruption

Because RDHx units are rack-agnostic and decoupled from the server chassis, they can be transferred, upgraded, or serviced without disrupting broader operations. Facilities can deploy them incrementally, starting with one rack and scaling as needed. Using standardized couplings and plumbing also reduces installation complexity, shortening deployment timelines.

More computing capacity within the same footprint

By offloading heat from critical server components to larger heat exchange surfaces, RDHx improves thermal transfer efficiency while enabling higher rack densities ranging from 20 to 80kW. This creates room to expand computing capacity within the same footprint. In some cases, reducing server fan load further optimizes energy use, freeing up additional headroom for AI systems under tight power constraints.

Building readiness for long-term cooling strategies

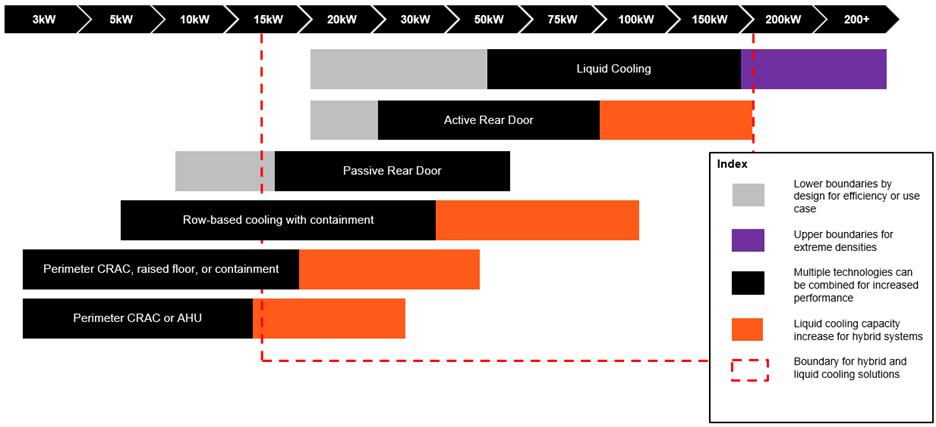

RDHx adoption gives operators hands-on experience with liquid cooling and prepares sites for higher-density upgrades (see Figure 4). The same chilled water loop can support direct liquid cooling, such as direct-to-chip or immersion cooling, by relocating coolant distribution units (CDUs). Facility teams can update the rear door manifolds and add circuit centers to manage flow. This approach expands thermal capacity while leveraging current assets.

Figure 4. Evolution of thermal management technology with increasing rack density; red boundary highlights conditions for viable data center liquid cooling.

Preparing data centers for high-density growth

Higher-density racks demand smarter, more precise thermal management. RDHxs offer a practical, scalable way to manage increasing heat loads without major infrastructure changes. Their modular design, deployment flexibility, and compatibility with existing chilled water systems make them a strong fit for legacy and modern data centers. RDHx solutions provide a foundation for liquid cooling strategies that support data center cooling needs.

Is your data center cooling ready to scale with the load?

RDHx solutions provide a foundation for liquid cooling strategies that scale with rising thermal loads driven by AI. Visit the Vertiv™ AI Hub to learn how Vertiv helps align cooling, power, and scale for what’s next.