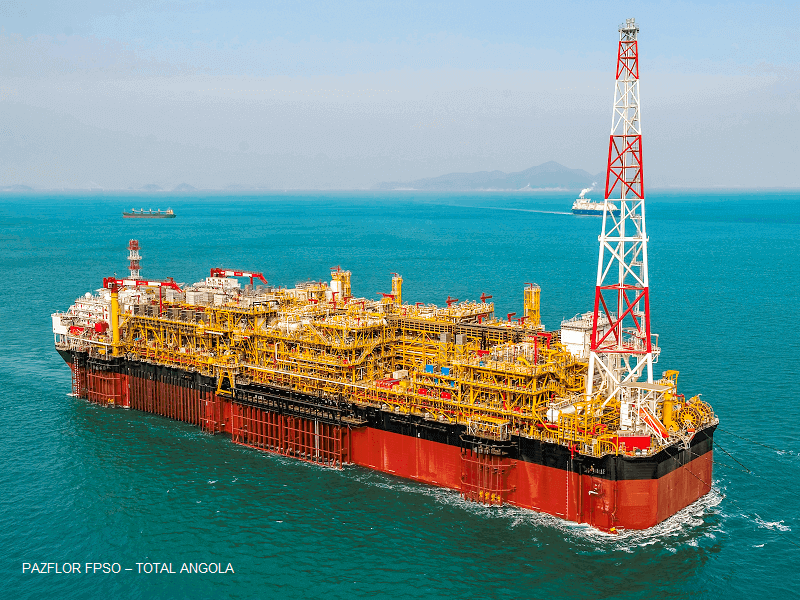

Downturn in the oil and gas industry is putting pressure on many operators to come up with innovative ways to reduce cost while improving operational efficiencies. Automation and digitization are increasingly being applied throughout the plant operations process. At the heart of it all lies safety, and companies who are able to leverage on new technologies while ensuring plant safety will have the edge from their competitors.

One approach by operators is to digitize and remotely manage offshore platforms and applications using the latest tools. Not only will this cut down on manpower utilization, but also allow operators to address issues of real estate. Offshore locations can now be designed with a smaller footprint.

With this approach come operational challenges including safety, cost, as well as regulatory compliance. One of the critical areas that need to be reassessed is the UPS used in the offshore production facility. The UPS is critical as it ensures power availability in the event of unexpected outages. But ordinary UPS solutions aren’t enough to handle the harsh environment of an offshore oil and gas platform. Below we have identified four key areas to consider when choosing a UPS for your offshore production facility:

1. Ability to operate in hazardous areas

Hazardous areas such as offshore oil and gas platforms require special precaution in the installation and use of equipment. It is critical for asset operators to understand the various hazardous locations and identify the best equipment to be installed in these areas.

The hazardous area designation of the asset takes into account the likelihood of combustible or explosive gas or vapors being present in that area. Electrical plant installed within Zone 1 or Zone 2 areas must be suitably certified for operation in that Zone, gas group and temperature class.

2. Solution must be appropriately certified

An effective and safe UPS solution must be certified to international standards of safety so you can be assured that they are able to operate in dangerous locations. The IECEx is a system to facilitate international trade in equipment and services for use in explosive atmospheres, while maintaining the required level of safety. Equipment, especially electrical, and their use in these areas are covered by a wide range of IEC Standards and are generally highly regulated.

3. Small footprint, space saving

Asset designers are increasingly pursuing means of saving cost by removing steel from the structure. Since the steel used in the platform is a direct function of the plant weight and dimensions it must support, any saving in real estate on the platform carries within it an important reduction of the platform dimensions and overall asset CAPEX.

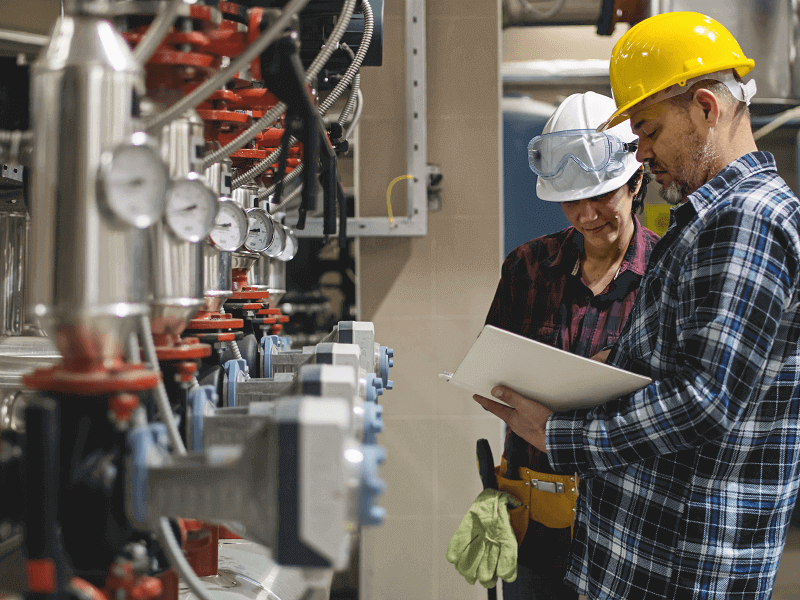

4. Ease of maintenance and service

Because of the risks in an offshore oil and gas environment, installed equipment must be easily managed from installation throughout lifecycle. At the same time, by definition it is prohibited to compromise the UPS’s flame path while it is energized making routine verification of the UPS’s health and performance a challenge.

The Vertiv Solution

Vertiv’s Chloride® XP systems feature a fully industrial design, approved by some of the world’s leading Oil and Gas operators, employing a galvanic isolation transformer and fully controlled SCR rectifier bridge technology. This is unique in the market compared to the conventional approach of installing off-the-shelf switch mode rectifiers in off-the-shelf Ex’d boxes, then paralleling them together to achieve the required rating. The conventional approach demands considerable real estate on the platform and is electrically far less reliable.

Chloride XP systems also feature:

- The smallest footprint in the market

- No need to reduce reliability by paralleling multiple modules to achieve required power

- Proven industrial design with isolation transformer and SCR rectifier

Innovative EX’d colour graphic HMI facilitating full access to all performance data while the UPS is energized

Vertiv has developed in-house expertise to help you understand all the key points related to increased safety areas. We can help you design the best suited UPS system according to the type of hazardous atmosphere. You can learn more about our Industrial UPS portfolio here or talk to one of our representatives.